I. Introduction

Many businesses worldwide partner with shower drain manufacturers in China for cost-effective and high-quality solutions. This article outlines the five crucial steps for effective interaction with a Chinese linear shower drain manufacturer. When you are a small business or an executive distributor, it will assist you in recognizing the measures in enhancing the overall production while maintaining quality.

II. 5 Key Steps in Working with Chinese Linear Shower Drain Factories

1. Design and Specification Development

First of all, when starting a job, one should have rather adjusted his/her view of what he/she wants to produce. This phase enables validation of your requirements against the capability of your factory so as to come up with a proper design.

Key Considerations:

- Material type (stainless steel, brass, aluminum)

- Drain length, width, and depth

- Finishes (brushed, polished, matte)

- Water flow efficiency and drainage patterns

- Additional services and products (anti-clog technology, odor traps, personalized grates)

Use the following regarding source: Most shower drain manufacturers have design consultation services. For more details like dimension and material they can consult with them for better guidance.

2. Factory Selection and Evaluation

It is important to understand that not all manufactures are the same. Select the right factory that produces quality, affordable, and robust equipment for the long term benefits.

How to Choose the Right Manufacturer?

In this case, it is important to evaluate their work experience and credibility in the medical field.

- Demand ISO certifications and product testing reports.

- Demand to inspect the factory tours either virtually or physically.

- Partly check with the current clients and customer feedback.

- It is key that one evaluates their MOQ or the manufacturing capacity that they have.

Fact: More than 80% of the plumbing products are imported from China; therefore, it’s a marine of opportunities.

3. Communication and Collaboration

The communication should be free and unambiguous once you select a particular manufacturer. Miscommunication means production errors, delay in operations, or even production of substandard goods.

Best Practices for Effective Communication

- Use complex drawings on a computer and models to avoid ambiguity and confusion.

- Check material substance and tolerance before starting the production process.

- The roles of setting the expected time for production and delivery schedules are as follows.

- Specify a full time project manager for the task or if necessary turn to a sourcing agent.

Tip: While most Chinese factories deal with export customers frequently, do keep it simple: if you aren’t thoroughly clear, neither will they be. Do not use industry-specific terms that some people may not fully understand.

4. Production and Quality Assurance

As soon as a product is begun, then it is a real challenge to maintain high quality depending on the production process.

Quality Assurance Checklist

- They should avoid full scale production before obtaining samples of the intended product.

- To meet this challenge, third-party inspections should be adopted to check on the quality.

- This means testing for corrosion resistance of the implemented material, effectiveness of water flow, and sturdiness.

- Ensure that the packaging adopted for the product conforms to shipping and retail market needs.

Stat: It has been estimated that poor quality control in international sourcing contributes to as much as 70% of product defects. The fact is that by having a periodic examination to check its state, one can avoid pitfalls that may cost a lot of money.

5. Compliance and Certifications

Before importing, there are regulations that have to be met by the product in the country where you are located. Otherwise, there may be further delays in shipping or even fines.

Important Certifications to Check

- CE Certification (For European markets)

- UPC Certification (For North America)

- ISO 9001:2015 (Quality Management)

- NSF Certification (For water safety compliance)

Tip: There are some companies that design and produce shower drains for compliance to the international standard. Ask for compliance documentation upfront.

III. Why Choose YZDRAIN?

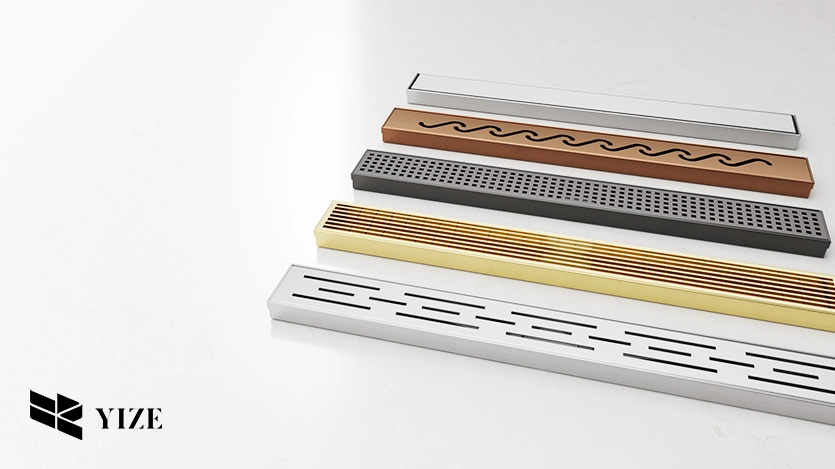

YZDRAIN is one of China’s leading Shower Drain Manufacturers that specialise in OEM/ODM services and offer quality to their customers. These are the reasons why many businesses go for YZ DRAIN:

- Custom Design Expertise – Designing and manufacturing of linear drains to fit specific needs.

- Premium Material Selection – Durable stainless steel with multiple finishes.

- Stringent Quality Control – Pre-production, mid-production, and final inspections.

- Compliance with Global Standards – Certified for international distribution.

- Reliable Supply Chain – On-time delivery and well-organized logistics.

YZDRAIN is a reliable manufacturing company that provides affordable, high quality shower drain products and services.

IV. Conclusion

If you are planning to get into OEM production, always ensure that you research, communicate with the Shower Drain Manufacturers, and ensure quality. Cooperating with shower drain manufacturers in China is indeed a good idea that should be implemented correctly. These are the five steps that guarantee a successful collaboration from the design phase to the finalization of compliance. One has to choose the correct factory, manage communication, and establish that quality is a priority to avoid these mistakes.

With such manufacturers as YZDRAIN, you can likely get well-priced and high-quality shower drains, which can be designed to order. If you are venturing into a new market sector or you are on an expansion spree, China is a good place to look for shower drains!

FAQs

Q1: How do I find a reliable shower drain manufacturer in China?

You should look for credible manufacturers, consequently, read clients’ feedback, request for samples, make virtual or real site visits.

Q2: What is the usual MOQ for Chinese Shower Drain Manufacturers?

MOQ is different; however, generally, most of the manufacturers have MOQ of 100-500 pieces for an order. Some offer lower MOQ

Q3: How long does it take to manufacture OEM shower drains?

Approximate lead time is within 3-6 weeks; this depends on the quantity of orders and special customization.