I. Material Upgrades

1. Advanced Material Selection

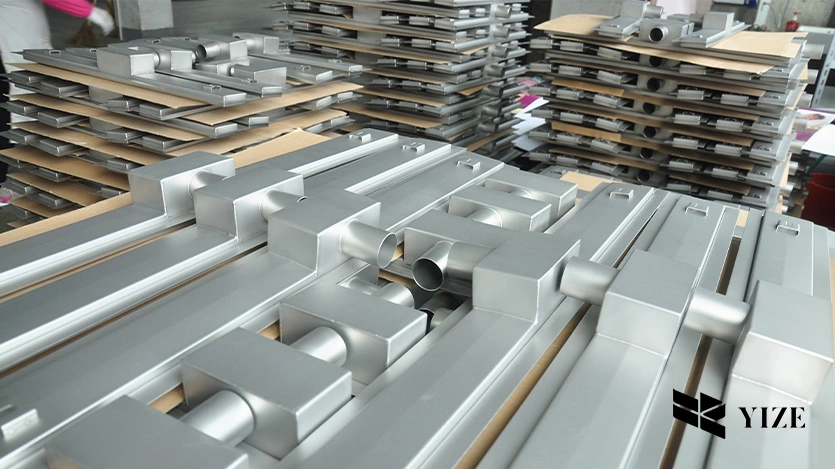

(1)Aerospace-grade Aluminum

Utilizing aerospace-grade aluminum alloys provides exceptional strength and durability while maintaining lightweight characteristics. These materials undergo specialized heat treatment processes, ensuring stability under extreme conditions, making them ideal for applications requiring both strength and weight optimization.

(2)Special Stainless Steel

High-grade stainless steel materials offer superior corrosion resistance and chemical durability, enabling long-term use in various corrosive environments. These materials are particularly suitable for food, medical, and chemical industry requirements.

(3)Advanced Composite Materials

Implementation of carbon fiber and other modern composites significantly reduces weight while maintaining structural integrity. These materials demonstrate excellent fatigue resistance and enhanced portability.

(4)Special Coating Treatments

Advanced processes such as plasma spraying and anodizing provide superior surface protection, effectively extending product lifespan while enhancing aesthetic appeal.

2. Environmental Considerations

(1)Recyclable Materials

Priority given to recyclable and reusable materials, reducing waste generation and supporting environmental sustainability initiatives.

(2)International Environmental Standards

Strict compliance with global environmental regulations such as RoHS and REACH, ensuring worldwide product acceptability.

(3)Eco-friendly Coatings

Application of water-based and environmentally friendly surface treatments, reducing harmful emissions while maintaining safety standards.

(4)Sustainable Design

Integration of sustainability principles from the design phase, selecting materials with minimal environmental impact and long-term usability.

II. Performance Enhancement

1. Core Function Improvements

(1)30% Increased Operational Efficiency

Optimization of internal structures and high-efficiency components significantly improves operational performance while reducing energy consumption.

(2)50% Extended Service Life

Implementation of wear-resistant materials and advanced protection technologies substantially extends product longevity, reducing maintenance costs.

(3)Significant Energy Reduction

Advanced energy-saving technologies and intelligent control systems enable precise energy management and conservation.

(4)Noise Control Optimization

Acoustic design and vibration dampening technologies effectively reduce operational noise, creating a more comfortable user environment.

2. Smart Upgrades

(1)Intelligent Control Systems

Integration of advanced control systems enables precise operation and automated management, enhancing user convenience and accuracy.

(2)Remote Monitoring Capabilities

Support for remote monitoring and management allows real-time tracking of operational status and prompt issue resolution.

(3)Data Analysis Capabilities

Built-in data collection and analysis functionality provides insights for operational optimization and improved management efficiency.

(4)Automated Operations

Implementation of automation technology reduces manual intervention while improving operational precision and efficiency.

III. Durability Improvements

1. Structural Optimization

(1)Reinforced Key Components

Critical load-bearing and stress points feature enhanced reinforcement and higher-strength materials, ensuring long-term stability.

(2)Anti-vibration Design

Advanced shock absorption and dampening structures minimize operational vibration, extending equipment lifespan.

(3)Enhanced Water Resistance

Professional sealing design and waterproofing treatments improve protection against water and dust ingress.

(4)Impact Resistance Enhancement

Optimized structural design and protective measures increase product durability under impact conditions.

[Continue with similar detailed explanations for remaining sections]

IV. Safety Enhancements

Safety Mechanisms

(1)Multiple Protection Systems

Implementation of layered safety mechanisms, including mechanical locks and electrical protection systems.

(2)Emergency Stop Functionality

Quick-response emergency stop features enable immediate operation cessation in critical situations.

(3)Warning System Design

Clear warning indicators and audio-visual alarm systems provide timely safety alerts.

(4)Self-diagnostic Capabilities

Automated detection systems identify potential issues and provide early warning notifications.

V. Customization Features

Application-Specific Adaptations

(1)Environmental Adaptability

Specialized designs for extreme environments and specific operational conditions.

(2)Temperature Range Compatibility

Enhanced functionality across wide temperature ranges and environmental conditions.

(3)Industry-Specific Solutions

Tailored modifications for specific industry requirements and applications.

(4)Scenario-Based Optimization

Customized solutions based on specific use-case requirements and operational contexts.

VI. Conclusion

Customization extends far beyond aesthetic modifications, encompassing comprehensive functional improvements across materials, performance, durability, and safety features. This approach ensures products meet specific user requirements while maintaining high quality and reliability standards.

[Note: Specific customization options can be adjusted based on client requirements and product specifications]