I. Introduction

Stainless steel linear drains are known for their modern appearance and practical utility for those who choose to incorporate them into your bathroom. These drains not only look stylish and beautiful in your shower but also ensure proper draining of water. Although the process of installing a stainless steel linear drain may sound somewhat challenging, accomplishing it is not that difficult at all. The following are some general overviews as well as the detailed procedures that explain how it works, how to install it, and how to maintain it.

II. Benefits of Installing Stainless Steel Linear Shower Drains

1. Aesthetically Pleasing

The first benefit of stainless steel linear drains is that they are sleek and provide the homeowner with a contemporary look. In contrast to circular drains which are usually installed in the middle of the shower floor, linear drains can be easily hidden and incorporated into the floor thus giving the shower more elegance. They are aesthetically inclined to interconnect with several tile designs offer a graceful touch towards the bathroom.

2. More Space

The floors use line drains along the edge of the floor, which frees up much more space within the shower. This just enhances the flexibility of the flooring design because there is no need to slope the floor in several directions. If there is only one pitch towards the drain, then you can use wider tiles and this makes the shower area to look wider as well.

3. Easier Maintenance

Stainless steel has a high tensile strength and is resistant to corrosion. Since there are no curves on linear drains, they do not accumulate dirt and debris to cause clogging and water to stagnate. Contemporary look that does not allow dust and other particles to build up thus providing a clean showering zone without much hassle.

III. Tools and Materials Needed for Stainless Steel Linear Drain Installation

Before you proceed with the installation, you should have all the tools and materials ready for use. This will enhance the process and ensure that there are no intermissions over time. Here’s what you’ll need:

●Stainless steel linear drain

●Tape measure

●Tile cutter

●Adhesive (waterproof)

●Caulk and caulking gun

●Tile leveling system

●Thinset mortar

●Grout and grout float

●Waterproof membrane

●Rubber mallet

●Spirit level

●Safety gear (gloves, eye protection)

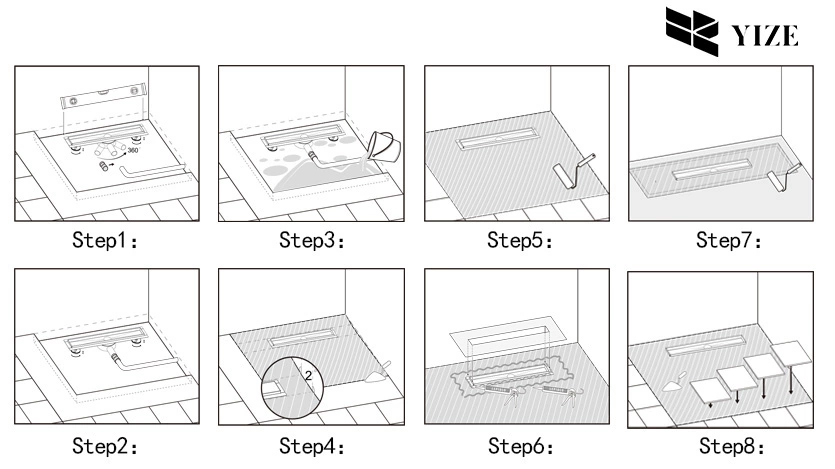

IV. 10 Instructions to Install Stainless Steel Linear Drain

1. Measurement:

First, take the dimensions of the space where the linear drain is going to be installed. The correct measurements are vital in order to ensure that the drain properly fits. Take measurements of the width and length of the shower floor and use a pin to determine the position of the drain hole.

2. Cut Out The Drain Hole:

Measure the size and shape of the drain hole, and then cut the drain hole on the shower floor. Ensure that the hole is big enough to contain the drain but small enough for the structure not to be weak. Cut the tiles with a tile cutter to ensure that the cuts are neat and accurate.

3. Apply Adhesive:

This process involves covering the part of the roof where the drainage pipe will pass through with waterproof adhesive. See to it that the adhesive will be spread out well, because this will hold the drain and will not allow any leakage of water. This is because allowing the adhesive to set for a few minutes gives it enough time to harden and increase in its bonding strength.

4. Install the Drain:

Align the stainless steel linear drain into the cut-out area and firmly ensure it adheres to adhesing properly. Ensure the drain is in the correct position with the shower floor and it is at the correct angle. If necessary, tap it gently into place with a rubber mallet.

5. Leveling The Drain:

After installation of drain, one may use a spirit level to check if the drain has been placed flat on the floor. This is crucial so that the water does not stagnate but flows out as required for the survival of the plants. If the drain does not slope, water will accumulate in certain areas in the long-term which is undesirable.

6. Securing The Drain:

Screw the drain where necessary or lock it on the brackets provided depending on the drainage unit design. Ensure that it is well secured to the floor and cannot be moved around during tile installation or in future. Make sure that the level is set correctly before proceeding to the next step.

7. Setting Tiles:

Spread thinset mortar around the drain and proceed to lay the tiles. Measure and cut the tiles properly so that they fit perfectly around the drain hence arranging them in a manner that meets the edges of the drain. These can be applied to tile leveling system that help in keeping the tiles evenly placed to reduce cases of lippage.

8. Sealing The Tiles:

After you have installed the tiles, leave the thinset to dry as recommended by the manufacturers. Next, spread the grout in between the tiles using a grout float. It is also important to make sure that the grout is applied uniformly in equal proportions around the drain, and between the tiles.

9. Caulking the Drain:

Once the grout has set, cover the edges of the drain with a waterproof silicone caulk to ensure that water cannot penetrate. It is necessary for avoiding leakage and making sure that there will be no water seeping through the exterior or walls of the building.

10. Final Touches:

Lastly, it is also important to clean the drain and tiles that are nearby with a sponge soaked in warm water just enough to wash away the remaining grout or adhesive on the tiles. Before using the shower, let the installation cure for at least 24hrs to ensure that everything is properly set. Look for any tiles that are loose or any gaps in the seam, and make any necessary adjustments accordingly.

V. 8 Safety Measures to Follow When Installing a Stainless Steel Linear Shower Drain

1.Wear Safety Gear: Protect yourself from injuries by wearing gloves and eye protection whenever handling the metal.

2.Ensure Proper Ventilation: When using adhesives or caulking, they should be done in well-ventilated areas, because of the fumes which can be inhaled.

3.Check for Electrical Wiring: Before beginning to saw through the floor, one should check whether there are any wires or other utilities in that area.

4.Handle Tools with Care: Cutting the tiles with sharp tools such as tile cutters should be done carefully to avoid injuries.

5.Use a Stable Work Surface: Make sure your work area is strong and firm, especially when cutting tiles to avoid accidents.

6.Read Manufacturer Instructions: The installation of the drain should be done strictly according to the manufacturer’s specifications.

7.Turn Off Water Supply: Check whether the water supply is off before proceeding with the installation process.

8.Test for Leaks: After installation, it is advisable to run water through the drain in order to ascertain any defect in the drain such as leakage.

VI. How to Maintain Stainless Steel Linear Shower Drain?

Caring for your stainless steel linear drain is not very tedious. Preventing the buildup of soap scum and debris can be done through proper cleaning with mild soap and water. Do not use corrosive substances that would otherwise react with the stainless steel and cause it to degrade. For more thorough cleaning, you should lift the grate and scrub the inside of the receptor area with a soft brush. Scrubbing and inspecting the caulking and grout will go a long way in preventing leaks from occurring.

VII. Why Choose YZDRAIN?

●Top Shower Drain Manufacturers and Suppliers: YZDRAIN has been associated with the manufacture of some of the finest linear shower drains made of stainless steel. This makes them observe high standards of quality so that they can be sure the drains they put up are going to last.

●High-Quality Standards and Process Technology: All the YZDRAIN products are produced with high quality and with the latest of the process technology to make them very durable and reliable.

●Excellent Durability Solutions: Stainless steel does not corrode easily, and thus, the products being produced by YZDRAIN are durable, even where there is much humidity.

●Customer Feedback: Most of its customers have commended YZDRAIN for the flair designs as well as the durability of its products hence deserving its reputation in the market.

VIII. Conclusion

The shower wall linear drain stainless steel is one of the best products to enhance the appearance of your bathroom while improving functionality. Performing all these steps will help you to successfully install this shiny and stylish drain and enjoy its usage for many years. Your stainless steel linear drain will therefore stand the test of time in terms of drainage ability and value added to your home provided it is maintained and cared for as required.

FAQs

1. Can I install stainless steel linear drain to my house without the help of a professional?

Yes you can install it yourself but it requires right tools and instructions on how to do it.

2. When should I clean my linear drain?

It’s best to clean it at least once a week to avoid clogging or the creation of a sludge layer at the bottom.

3. Which tiles are most suitable for use with linear drains?

The use of larger tiles is also advisable because they ensure there is a smooth gradient towards the drain.