I. Initial Consultation & Requirements

1. Design Consultation

– Schedule initial meeting

– Discuss project requirements

– Review architectural plans

– Define design preferences

2. Technical Requirements

– Flow rate needs

– Installation environment

– Space constraints

– Specific performance requirements

II. Customization Options Selection

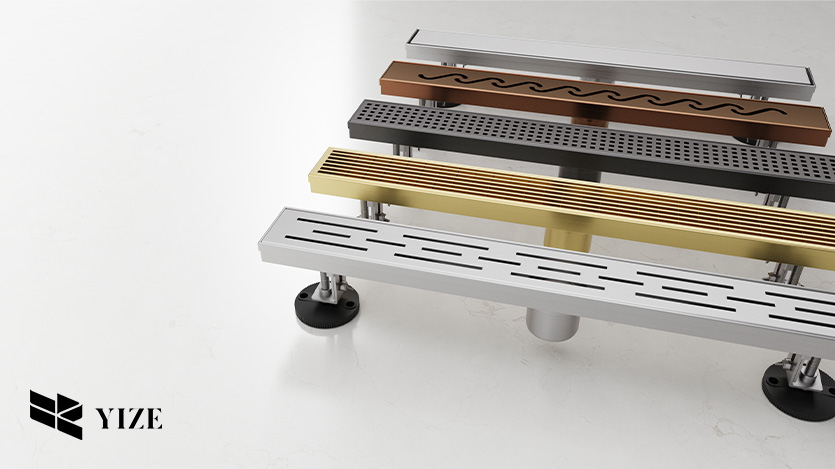

1. Size Customization

– Select dimensions from standard options

– Request custom measurements

– Review technical feasibility

– Confirm installation compatibility

2. Logo Customization

– Submit logo artwork

– Choose placement location

– Select printing/engraving method

– Review proof design

3. Packaging Design

– Standard white box option

– Custom color box design

– Brand-specific packaging

– Special packaging requirements

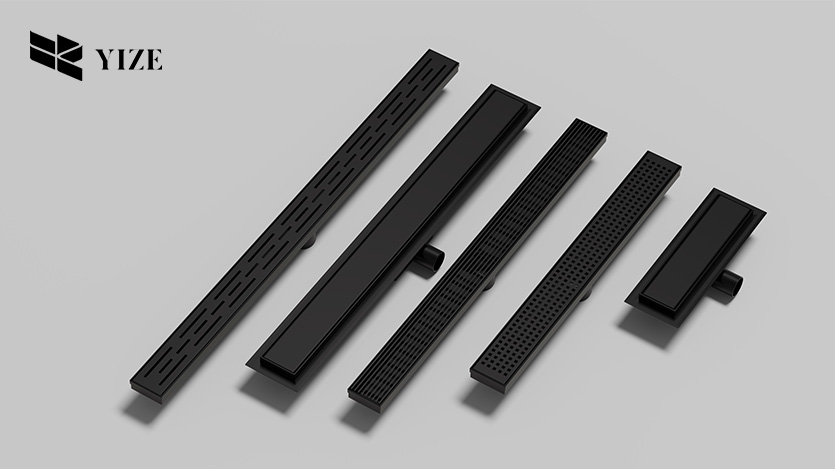

4. Color Selection

– Choose from 16 standard colors

– Custom color matching available

– Surface finish selection

– Sample approval process

5. Panel Design

– Select from existing patterns

– Custom pattern development

– Material specification

– Finish selection

6. Surface Treatment

– PVD coating options

– Bronze sealing

– Electroplating options

– Brushed finish variations

III. Technical Innovation

1. Dry-Wet Siphon System

– Enhanced water flow (+50%)

– Anti-clogging design

– Improved odor isolation

– Maintenance-free operation

2. Performance Features

– Water flow capacity

– Anti-odor effectiveness

– Durability testing

– Cleaning accessibility

IV. Order Processing

1. Quotation Phase

– Initial price estimation

– Tooling cost evaluation

– Volume-based pricing

– Payment terms

2. Sample Development

– Prototype creation

– Sample testing

– Client approval

– Modifications if needed

3. Production Planning

– Material procurement

– Production scheduling

– Quality control measures

– Delivery timeline

V. Quality Assurance

1. Testing Procedures

– Performance testing

– Durability checks

– Material verification

– Quality inspection

2. Documentation

– Technical specifications

– Installation guides

– Maintenance manuals

– Warranty information

VI. Support Services

1. Technical Support

– Installation guidance

– Maintenance training

– Problem resolution

– After-sales service

2. Customer Service

– Order tracking

– Feedback collection

– Issue resolution

– Regular follow-up

VII. Tooling Investment

1. Mold Cost Policy

– Volume-based assessment

– Cost sharing options

– Amortization plans

– Minimum order requirements

2. Cost Optimization

– Volume discounts

– Long-term partnerships

– Exclusive agreements

– Investment recovery plans

This comprehensive customization process ensures that each client receives a product that perfectly matches their requirements while maintaining high quality standards and efficient production timelines.