OUR PARTNERS

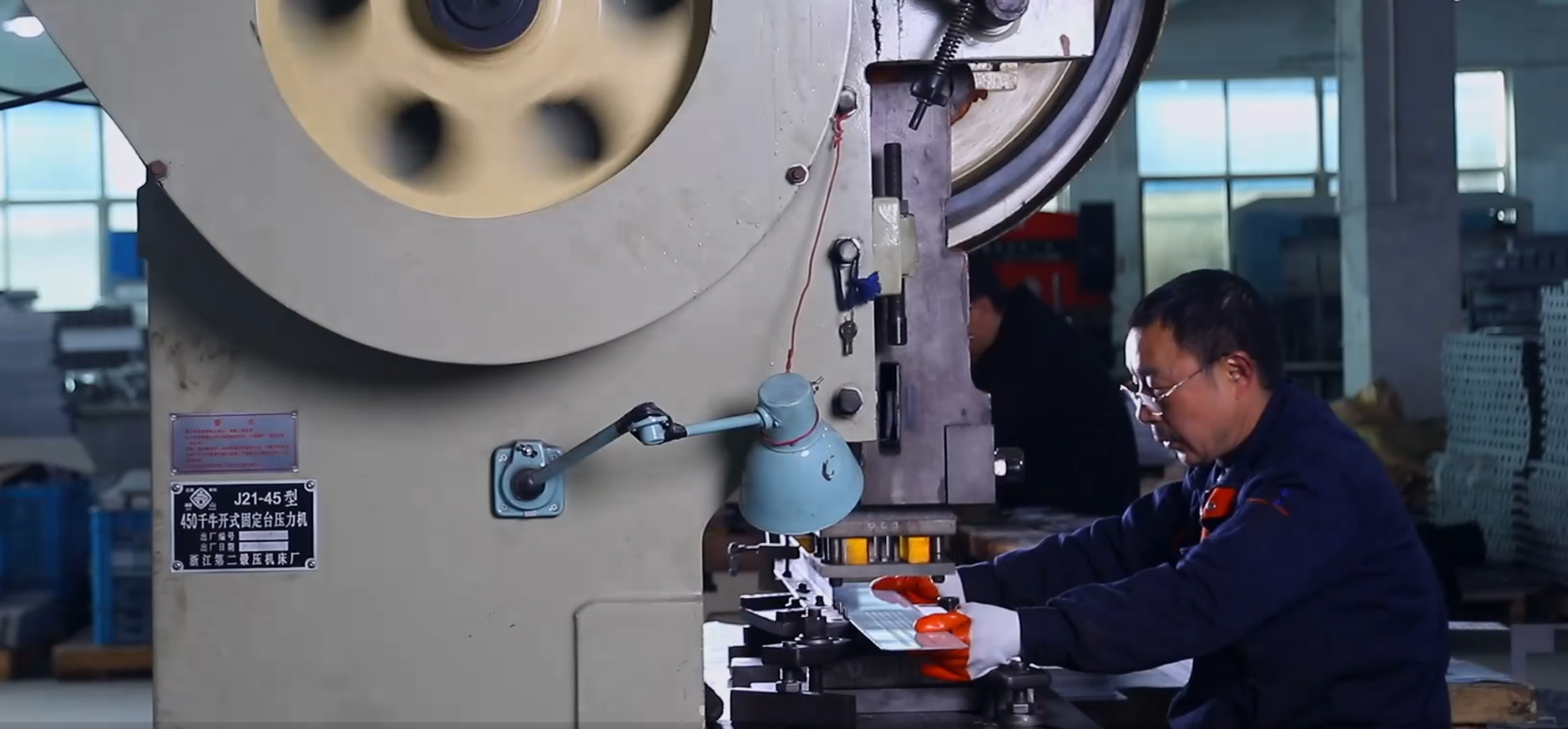

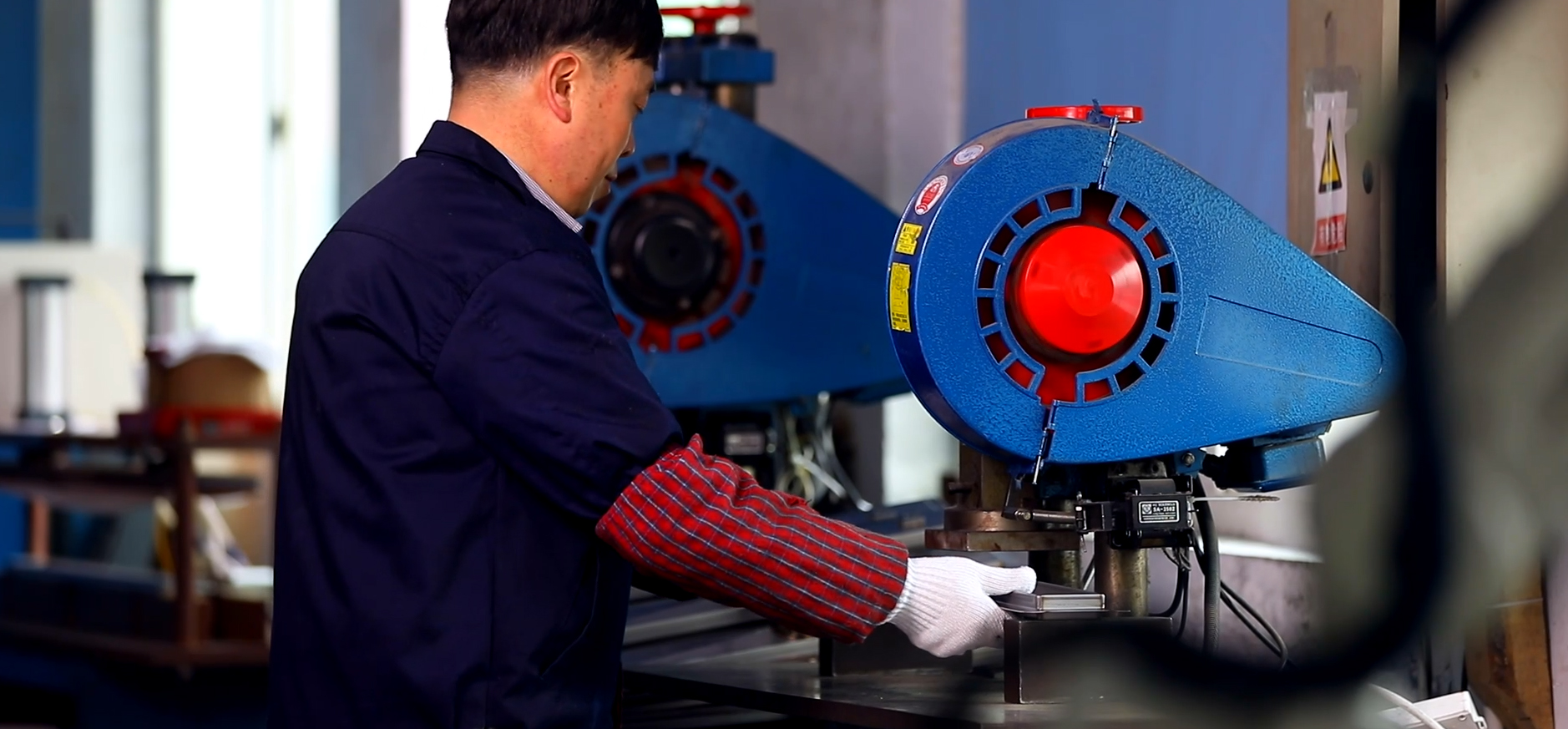

The process of making the floor drain

Punching offers a simple and effective way to create holes in metal workpieces.

V-shape,U-shape and channel shapes can be produced by bending in ductile materials.

Polishing can reduce roughness to obtain the bright, flat surface.

By using the principle of high heat and cooling, welding can join materials.

Sizes and shapes of workpieces can be changed to meet various needs.

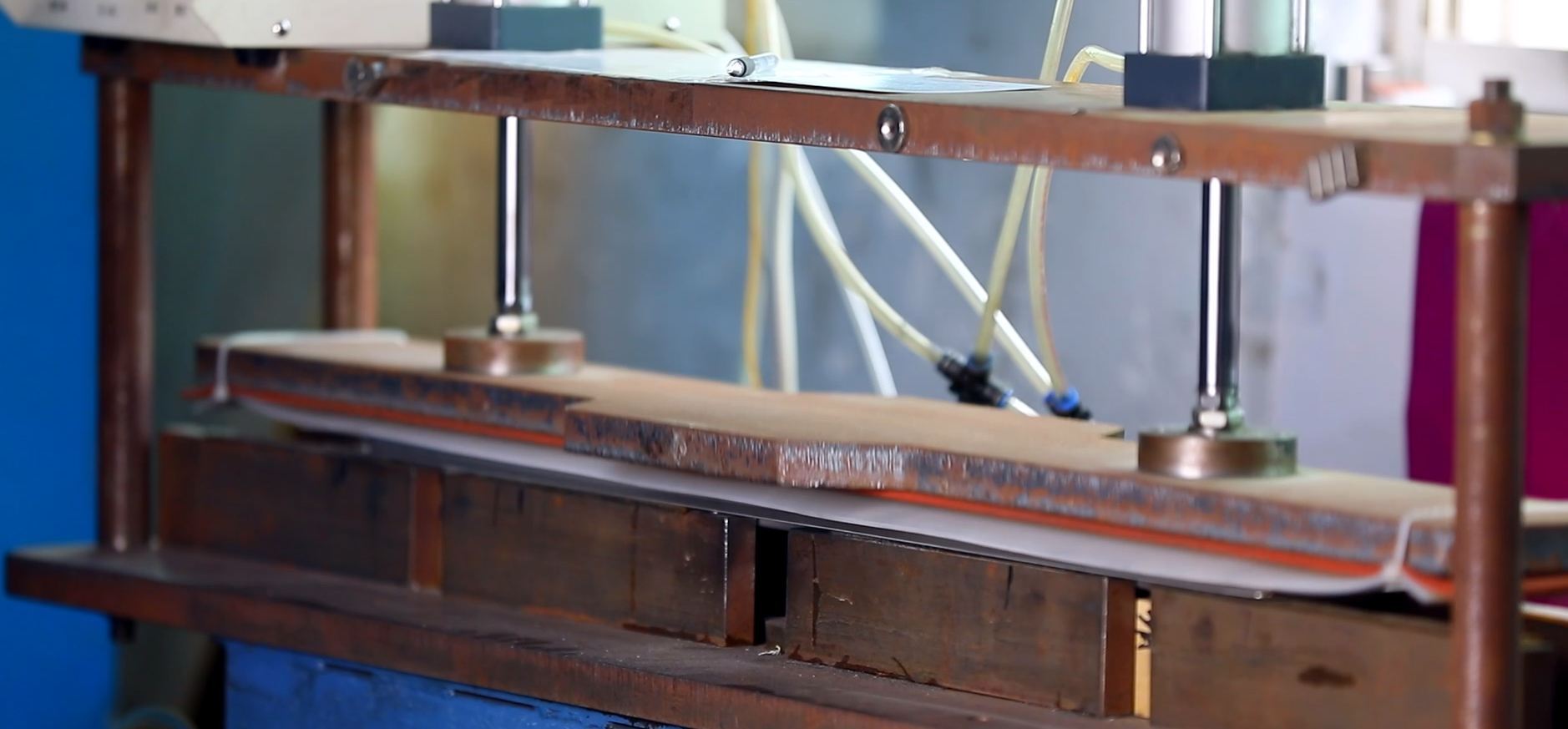

Rigorous testings have been operated to guarantee quality and performance.

Sand Blasting

Sand blasting uses the impact of sand particles on the surface to prolong durability.

Packaging

Careful packaging provides maximum protection and avoids

Complete product testing process

Detection QC

Detection thickness

Tensile test

Salt spray test

Valuable words from our customers

Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magn.

I have been purchasing from Yize for more than 5 years, their service exceeds my expectations, and I am very happy to cooperate.

Michael Wilson - CEO of Tozee

During the COVID-19, the products produced by Yize helped me expand my business line, thank them for their service

Patricia Bogle - CEO of Manan

Yize is an excellent supplier of floor drains. They have very professional production experience and are worth making friends in this industry.

Joseph Hyde - CEO of Moiz